Identify the Basic Quality Tool Shown in the Figure Above

The tool maps out a sequence of events that take place sequentially or in parallel. The structure provided by the diagram helps team members think in a very systematic way.

What Are The 7 Basic Quality Tools Lucidchart Blog

Seven tools of quality The Old Seven The First Seven The Basic Seven Quality pros have many names for these seven basic tools of quality first emphasized by Kaoru Ishikawa a professor of engineering at Tokyo University and the father of quality circlesStart your quality journey by mastering these tools and youll have a name for them.

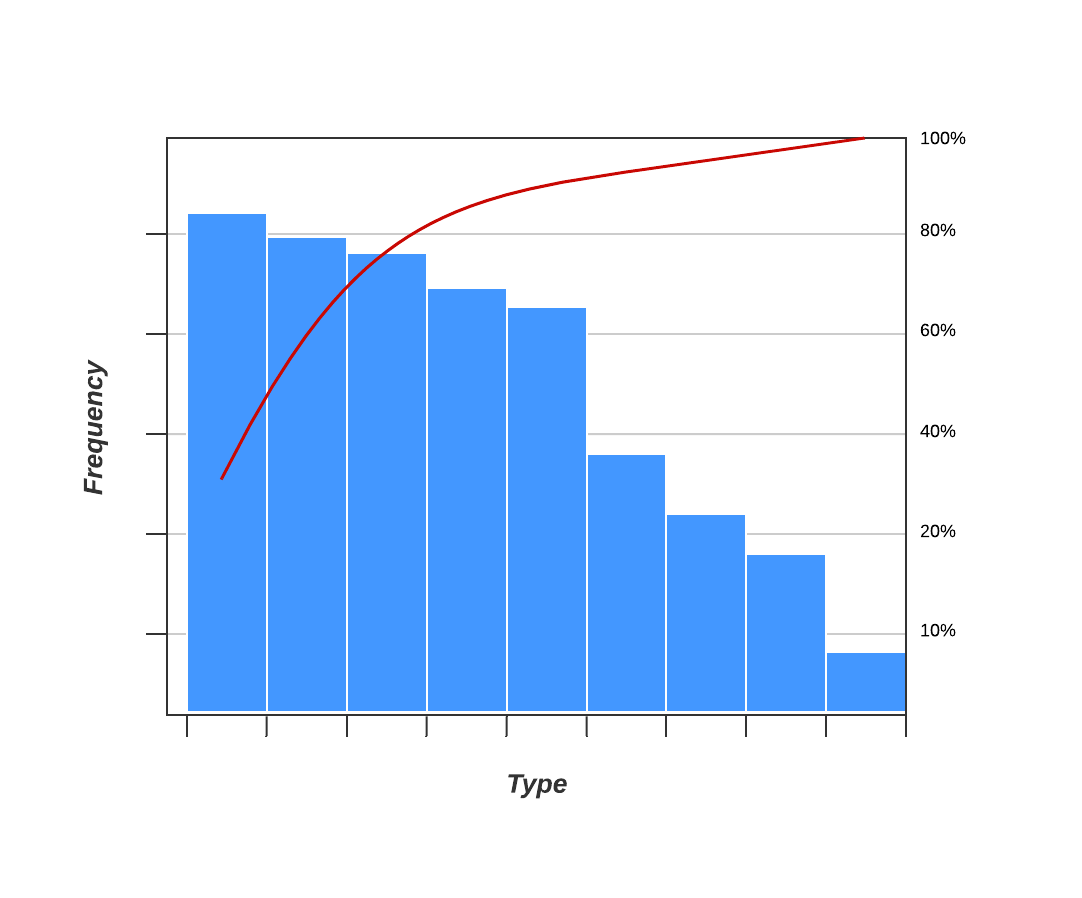

. This handy tool allows you to easily compare how well your data fit 16 different distributions. The refinerys quality control manager calculates that the new standard deviation is 02 octane. Pareto Analysis is one of the 7 basic quality process tools and is applied across many industries by Managers to improve the business and quality.

18 LABORATORY QUALITY CONTROL 181 Introduction This chapter addresses internal laboratory quality control QC the purpose of which is to monitor performance identify problems and initiate corrective action. 8020 are just a figure it can vary as 7030 or 955. If project requirements are more stringent than typical laboratory QC criteria the project manager and the laboratory should.

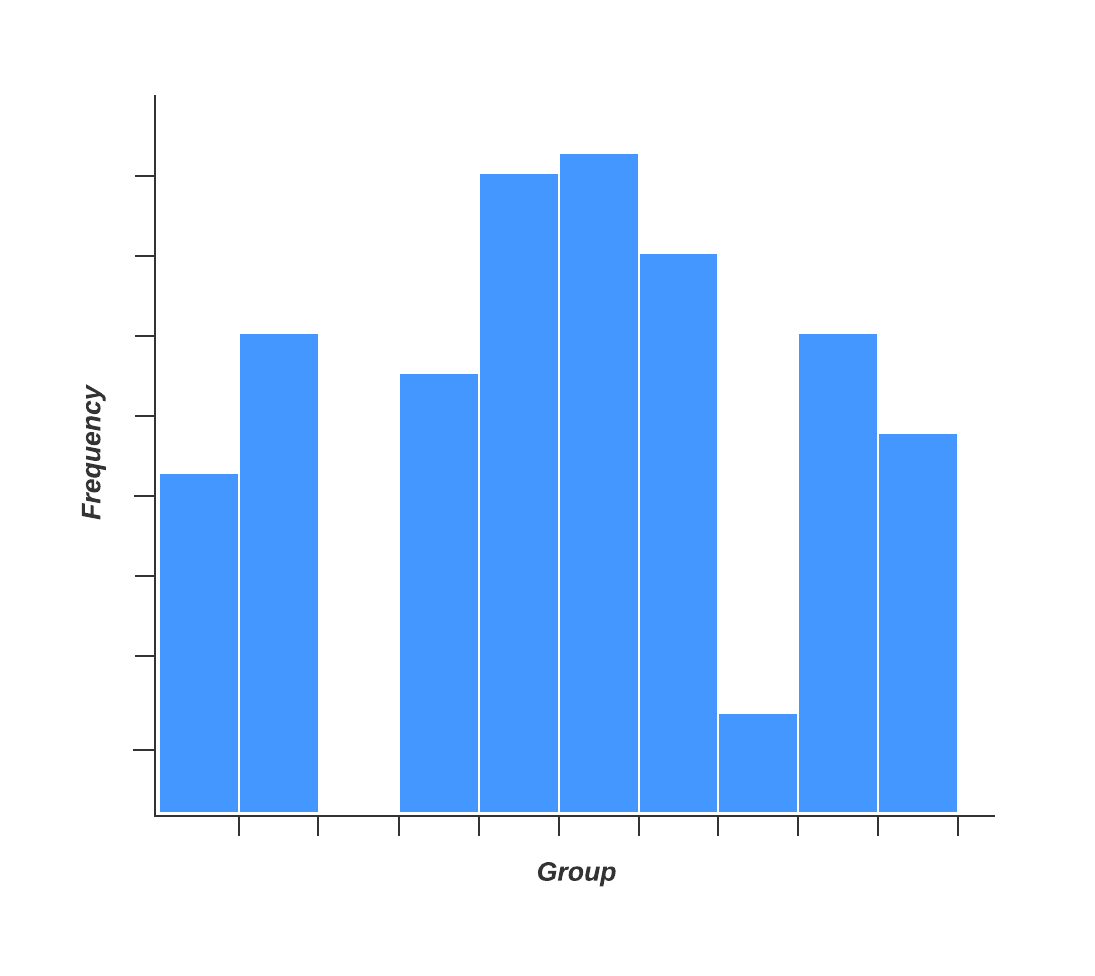

Identify the basic quality tool shown in the figure above. The flow chart can be used to understand a complex process in order to find the relationships and dependencies between events. As an example a human resource department may track the number of questions by employees per category per day.

Quality Function Deployment QFD and House of Quality HOQ is a structured approach for defining customer requirements and translating design specifications or product control characteristics in the form of a planning matrix. When it is applied to the software industry the Pareto Principle can be quoted as 80 of defects are contributed by 20 of the code. List Of The 7 Basic Quality Tools.

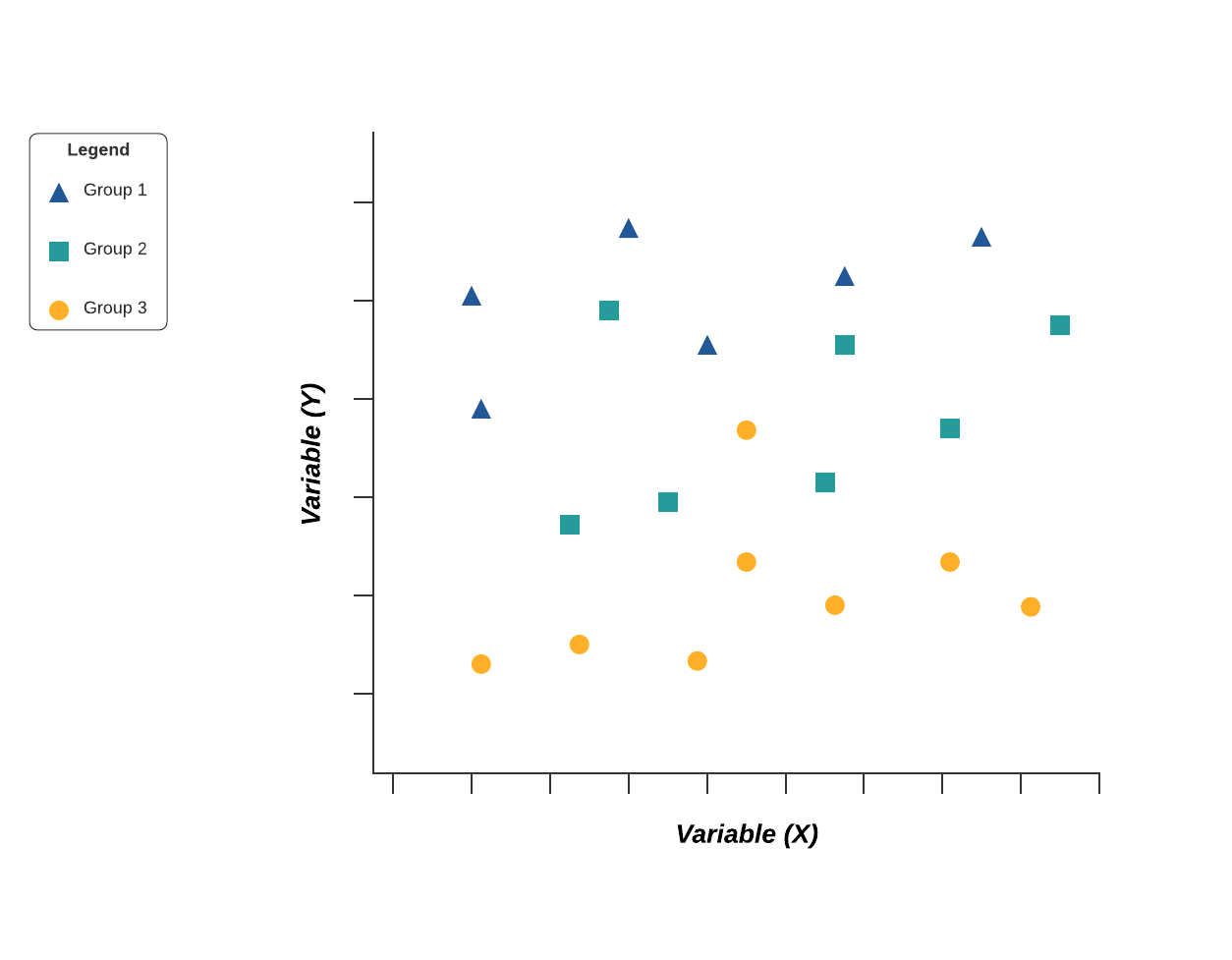

A new refinery process is installed that produces fuels with less variability. The better the correlation the tighter the points will hug the line. When the quality of surface finish is to be indicated by the roughness grade number in the surface finish symbol the grade number is written in the same place of the roughness value the Figure-A.

OA Run chart B Bone diagram C Cause-and-effect diagram D Histogram E Check sheet OF Pareto chart G Effect chart H Scatter diagram 1 Flowchart Identify the basic quality tool shown in the figure above. A Cause-and-Effect Diagram is a tool that is useful for identifying and organizing the known or possible causes of quality or the lack of it. Heres what an example hazard identification workflow would look like on this site.

The concept behind the seven basic tools came from Kaoru Ishikawa a renowned quality expert from Japan. This is one of the basic quality tool that can be used for analyzing a sequence of events. If the variables are correlated the points will fall along a line or curve.

A check sheet might be used to track the number of times a certain incident happens. We all are familiar with Flowchart since our school or college days. This cause analysis tool is considered one of the seven basic quality tools.

Quality control through Inspection Method is shown in the following Figure 273. In other words using QFD allows the charting of customer wants and the technical hows which results in a better understanding of design. The scatter diagram graphs pairs of numerical data with one variable on each axis to look for a relationship between them.

A check sheet is a basic quality tool that is used to collect data. Which of the following quality tools are also known as fishbone diagrams or Ishikawa diagrams. Given that this feature is a bore and can suffer prob-lems with its size form orientation and location explain how only a size tool and a location tool are able to impose all the necessary controls.

According to Ishikawa 95 of quality-related problems can be resolved with these basic tools. Due to default imposition of the Envelope Rule by the Y145 2009 Standard which empowers the Rule. For our example we are going to look at best practice based on using the above software and app combination.

Widely used and possessing high reliability and validity this tool provides a measure of desired outcomes through the patient. See the Figure above. Completion of work pacages is done after project planning.

To identify the distribution well go to Stat Quality Tools Individual Distribution Identification in Minitab. Depending on the tools and mechanisms you use to identify hazards in the workplace you will be looking at a different example and workflow. Identify the basic quality tool shown in the figure above.

However identifying quality standards occurs before the Identify Risks process. In the same way engineers must take a special look to points beyond the control limits and to violating runs in order to identify and assign causes attributed to changes on the system that led the process to. Operations Management questions and answers.

The R-chart generated by R also provides significant information for its interpretation just as the x-bar chart generated above. The refinerys quality control manager takes a new set of samples and charts a new frequency distribution diagram as shown in Figure 144. A Run chart B Pareto chart C Flowchart D Effect chart E Bone diagram F Scatter diagram G Control chart OH Cause-and-effect diagram OD Histogram OJ Check sheet.

It produces a lot of output both in the Session window and. R-chart example using qcc R package. In other words it enables the entrepreneur to identify the points at which deviations from standard set start.

Another tool to measure healthcare quality is Aiken and Patricians 2000 NWI-PES tool a 57-item survey that measures nurse recruitmentretention job satisfaction nurse safety and patient satisfaction providing a measure of the culture of excellence. Enlisted below are the top Quality Management Control and Improvement Tools that are available in the market. Some of the benefits of constructing a Cause-and-Effect Diagram Viewgraphs 2 are that it.

It is an advanced method or technique used to control the quality of a product. Identify risks sounds like a good choice. Since the previous project manager did not finish planning continuing to execute the project management plan should not be next.

A If the surface roughness is obtained by any production method other than machining the grade number of surface roughness for example N10 is indicated in. Identify the basic quality tool shown in the figure above. The key to successful problem resolution is the ability to identify the problem use the appropriate tools based on the nature of the problem and.

Air Source Heat Pump And Solar Water Heating Combined Hydronic Heating Systems Heat Pump Solar Water Heating

Pin On Analysis Agile Delivery

Using Diffraction Gratings To Identify Elements Visible Spectrum Contemporary Bathroom Designs Classification

Diagram Of Three Classes Of Levers Teaching Science Science Lessons Basic Math Skills

Project Management Plan Pmp Template Project Management Life Cycles Activities How To Plan

Line Graph Of Position In Meters Versus Time In Seconds The Line Begins At The Origin And Is Concave Up With Its Slop Line Graphs Equations Charts And Graphs

Crystal Healing Reference Chart Printable Instant Download Etsy Crystal Healing Chart Crystals Healing Properties Crystal Meanings Charts

What Are The 7 Basic Quality Tools Lucidchart Blog

What Are The 7 Basic Quality Tools Lucidchart Blog

Customer Journey Map Template Ux Hints Customer Journey Mapping Journey Mapping Experience Map

What Are The 7 Basic Quality Tools Lucidchart Blog

Sipoc Diagram Business Process Workflow Diagram Leadership Skill

Seo How To Do Onpage Seo On Your Website Blog Page Seo Services Seo Optimization Seo Services Company

Look At The Whole Picture For Root Causes Of Disease Personalized Medicine Disease Physical Activity Level

Figure 1 From Quality Risk Management Qrm Of Active Pharmaceutical Ingredients During Transportation By Using Fmea T Risk Management Risk Analysis Management

7 Ways To Analyze A Customer Journey Map Customer Journey Mapping Journey Mapping Customer Experience Mapping

Chartexpo Best Data Visualization Tool Data Visualization Tools Data Visualization Visualization Tools

Comments

Post a Comment